Reliable heat starts long before equipment ever reaches a production floor. The best manufacturers build consistency through strict checkpoints that follow each component from raw metal to final assembly. These controls shape how well cartridge heaters, custom industrial heaters, and other industrial heating accessories perform under real stress.

Material Screening Steps That Uphold Heater Element Durability

Quality begins with the metals chosen for resistance wire, sheaths, terminals, and insulating compounds. Each batch is tested for purity, tensile strength, and corrosion resistance to ensure it aligns with long-term operating requirements. A trusted industrial heating elements manufacturer evaluates how each material responds to heat cycling, oxidation, and mechanical stress, because poor inputs lead to premature heater breakdown.

Different materials react differently once subjected to the temperatures required in heavy-duty applications. This screening process ensures compatibility with industrial heaters USA users depend on, especially those operating in environments with wide thermal swings or exposure to moisture, chemicals, or high pressure.

Coil Winding Checks That Maintain Uniform Thermal Output

Resistance wire must be wound with exact spacing to produce even heat along the heater’s length. Small inconsistencies create hot spots that reduce service life and affect the performance of cartridge heaters and other industrial heating products. During manufacturing, technicians inspect coil tension, alignment, and pitch before moving the assembly to the next stage.

Uniform winding ensures predictable heat generation across the entire surface area. That stability matters in molding, packaging, sealing, and processing systems where temperature fluctuations can ruin entire production runs.

Sheath Integrity Reviews That Secure Performance Under Heavy Load

The sheath protects internal components from contamination, pressure, and environmental wear. Checks focus on wall thickness, surface uniformity, and chemical composition to verify the sheath can withstand the extreme stress found in many industrial applications. Even minor defects can allow moisture or contaminants to reach the heating coil, leading to failure.

These inspections often include visual reviews, micrometer measurements, and surface finish evaluations. A dependable manufacturer treats the sheath not just as a casing, but as a vital protective barrier that affects every other aspect of performance.

Lead Connection Inspections That Confirm Stable Electrical Flow

Electrical reliability depends on secure connections between lead wires and internal terminals. Poor junctions can cause arcing, intermittent flow, or resistance spikes that damage equipment. Manufacturing teams check for proper crimping, weld accuracy, and insulation placement during this phase.

Lead connections must also withstand vibration, movement, and repeated thermal expansion cycles. That means choosing the right lead wire gauge, insulation type, and strain relief to match the heater’s operating demands.

Fill Density Verification That Supports Consistent Heat Transfer

Magnesium oxide or similar insulating compounds are packed around the wound coil to enhance heat transfer and protect the element. The density of this fill material influences both performance and lifespan. Too loose, and the heater loses efficiency. Too compact, and it risks electrical leakage or uneven heat distribution.

Verification involves confirming that the fill is evenly dispersed and reaches the manufacturer’s specified compaction rating. This step is essential for custom industrial heaters designed for extreme temperatures or rapid cycling.

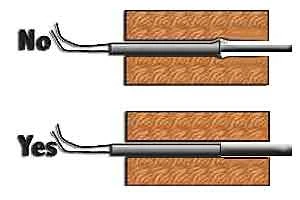

Dimensional Audits That Ensure Fit Within Tight Industrial Clearances

Cartridge heaters and related accessories often slide into machined bores with tight tolerances. Dimensional audits verify diameter, length, straightness, and roundness to ensure proper heat transfer and prevent premature wear. Deviations as small as a few thousandths of an inch can affect how well a heater fits and performs. These audits help ensure compatibility with existing equipment, especially in facilities running older machines that require precise heater replacements.

Temperature Cycle Testing That Validates Endurance in Demanding Runs

Cycle testing subjects heaters to repeated heat-up and cool-down operations. This exposes weaknesses in coil bonding, insulation stability, terminal strength, and sheath durability. Manufacturers use this data to refine production methods and confirm that heaters can withstand real-world stress. The results of temperature cycling often influence which industrial heating products fit best for high-demand applications like plastics, aerospace, or heavy manufacturing.

Terminal Quality Checks That Reinforce Long-term Reliability

Terminals must remain solid under continuous thermal expansion, vibration, and electrical load. Inspections verify torque strength, thread accuracy, and insulating barrier performance. A loose or weak terminal can compromise the entire heater.

These checks often include torque testing, thread-depth validation, and evaluations for oxidation or material fatigue. Each step supports safer operation in equipment that cannot afford unexpected downtime.

Final Assembly Scrutiny That Guarantees Dependable Field Operation

Before shipping, each heater undergoes a final review covering electrical resistance, insulation integrity, lead orientation, marking accuracy, and overall build quality. Manufacturers evaluate how every component works together, not just individually. This ensures a heater performs reliably once installed in the field.

The final inspection is the last opportunity to detect flaws before customers integrate the units into critical systems. For companies seeking durable custom industrial heaters and high-performance cartridge heaters, Thermal Corporation delivers products that meet demanding industrial standards.