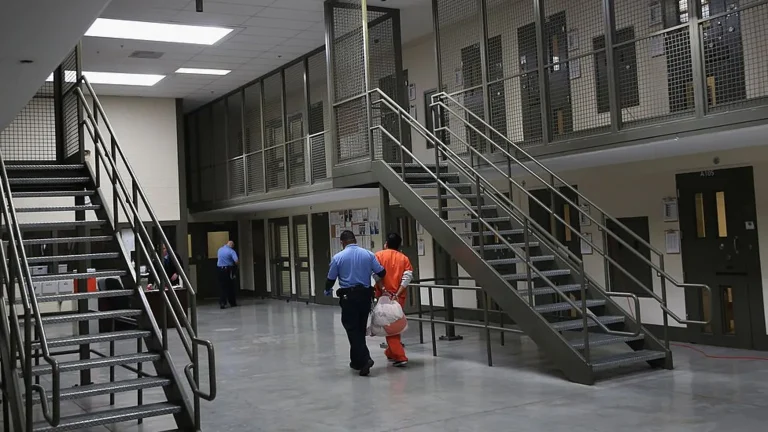

Daily activity inside a correctional facility is constant—doors open, close, and lock thousands of times a day under heavy supervision. Behind every one of those movements lies an engineering design meant to endure stress, impact, and time. What looks like an ordinary door in a detention center is actually a complex assembly built for unrelenting mechanical and security demands.

To Withstand Frequent Opening and Closing Cycles Without Mechanical Failure

Doors in detention environments face more repetitive motion than nearly any other type of door system. Inmates, officers, and maintenance staff rely on their consistent function every day. Standard commercial doors would quickly wear down under that kind of repetition. Reinforced detention center doors are built using engineered steel cores, precision hinges, and welded joints to handle thousands of cycles without loosening or jamming.

This level of reinforcement ensures the door’s moving parts remain functional even with minimal downtime. Security detention equipment contractors design and test these systems to operate continuously without the need for frequent repairs or hinge replacement. Each component—from the hinge pins to the latch bolts—is calibrated for long-term endurance that outlasts standard architectural assemblies.

Engineered to Resist Ongoing Abuse, Tampering, and Forceful Impacts

Inside high-security facilities, damage is not always accidental. Detention doors must be capable of withstanding kicking, prying, and impact attempts from the inside. Prison supply manufacturers use hardened steel skins and reinforced cores that distribute force evenly across the frame. These designs prevent weak points from forming at hinge or latch areas.

Inmates occasionally test door limits, either out of frustration or in attempts to tamper with locks. To counter this, detention equipment contractors integrate specialized reinforcement plates and tamper-resistant fasteners. The engineering goal is simple—contain force without distortion and keep integrity even after repeated abuse.

Ensures Continuous Security Function, a Critical Factor in Safe Facility Operations

A single malfunctioning door can compromise an entire security zone. That’s why reinforced detention doors must perform reliably during daily operations and emergency lockdowns alike. Each door plays a role in maintaining controlled movement between housing units, corridors, and secured areas.

To maintain this function, detention system engineers often use integrated locking systems and monitored control panels designed to detect mechanical issues early. Security detention equipment contractors test these systems to confirm they operate properly under stress. The result is a dependable layer of physical security that supports operational safety every hour of the day.

Maintains Structural Integrity over Many Years, Reducing Long-term Repair and Replacement Costs

Durability isn’t just a performance issue—it’s an economic one. Facilities that rely on standard-grade materials face frequent downtime and costly maintenance cycles. Reinforced detention center doors are constructed with high-tensile steel, welded reinforcements, and corrosion-resistant finishes that extend service life far beyond conventional products.

Modular jails and long-term correctional institutions depend on predictable performance over decades. Well-engineered reinforcement reduces the frequency of replacements and minimizes disruptions to daily facility routines. For administrators, this means lower total ownership costs and fewer interruptions to security protocols.

Prevents Parts from Bending or Warping Under Stress, Keeping Alignment Accurate

Door alignment is vital for proper locking and smooth operation. Without reinforcement, constant pressure from locking mechanisms and repeated slamming can bend or warp frames. Once alignment shifts, it can cause locks to fail, hinges to drag, or doors to stick. Engineered reinforcement maintains that alignment by distributing stress throughout the door body and frame rather than concentrating it on smaller components. By doing so, detention equipment contractors ensure consistent fit and motion even in high-use environments. This balance between rigidity and flexibility is the core principle behind modern correctional door design.

Supports the Weight of Heavy-duty Hardware like Specialized Locks and Continuous Hinges

The locks and hinges used in detention settings are far heavier than standard commercial-grade options. These systems can weigh several times more, depending on control features and materials. Reinforced doors must therefore be engineered to handle additional load without sagging or cracking over time. Continuous hinges and high-strength locking systems demand structural backing that won’t flex under tension. Security detention equipment contractors design reinforcements that integrate directly into the frame, supporting both vertical and horizontal loads. This ensures that every locking cycle remains smooth, accurate, and secure through years of service.

Reinforced Frames Are Necessary to Manage the Impact Energy of Attempted Forced Entries

In any high-security facility, there’s always the possibility of a physical breach attempt. Reinforced door frames are the first line of resistance against forced entry. They absorb and distribute impact energy, preventing frame separation and door detachment.

These frames often feature welded steel construction with integrated anchors designed for masonry or concrete installation. In modular jails, pre-engineered units rely on reinforced connections between panels and door frames to maintain stability under force. By combining frame and door strength, the system becomes a unified security barrier capable of withstanding extreme conditions.

Helps the Facility Meet Stringent National Safety Standards and Certifications for Secure Environments

Federal and state correctional standards require detention products to meet specific performance ratings. That includes resistance to tampering, impact, and mechanical stress over time. Reinforced detention doors help facilities achieve compliance with these regulations by providing measurable performance data during testing and certification.

Prison supply manufacturers design products that adhere to ASTM and ANSI standards while satisfying local building codes for correctional construction. This ensures not only physical safety but also accountability in facility design and maintenance. Meeting these requirements demonstrates that the detention environment operates under proven, tested engineering principles. Cornerstone specializes in manufacturing and installing reinforced detention equipment and secure door systems that meet these exacting standards, providing correctional facilities with durable, tested solutions designed for continuous, heavy-duty use.